Quality, Health, Safety and Environment

About Us

QHSE COMMITMENT

Resource Management – Role, Responsibility, Accountability and Authority

Our senior management is dedicated to the IMS’s success and ensures the allocation of necessary resources for its development, documentation, implementation, and maintenance. Clear roles, responsibilities, accountabilities, and authorities are defined across various functions and levels within our organization. The Ferrofab Management team collectively provides crucial resources, such as training, human resources, finances, technical support, and information services, to effectively execute and monitor the IMS management system.

QUALITY CONTROL

At Ferrofab, we believe that quality is the key driver behind customer satisfaction. By upholding thorough quality standards at every stage, from sourcing materials to manufacturing and delivery, we consistently deliver products that exceed customer expectations. Our unwavering dedication to quality has garnered us a reputation for reliability and excellence, establishing us as a trusted partner in the industry.

Ferrofab’s Integrated System Manual is prepared and based upon the requirements of the international quality management system standards ISO: 9001, ISO 14001, and and ISO 45001.

Safety

To further reinforce our commitment to safety, we have implemented the Incident & Injury Free (IIF) Program. This program encompasses HSE Observations, Statistics and Bulletins, and extensive trainings. By actively promoting awareness and encouraging proactive measures, we strive to prevent incidents and injuries in the workplace. Our robust program not only safeguards our workforce but also fosters a culture of safety excellence throughout our organization.

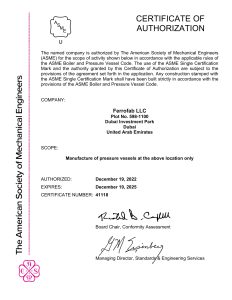

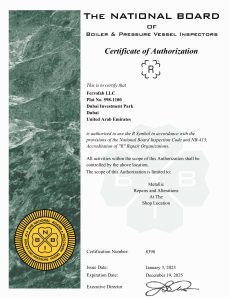

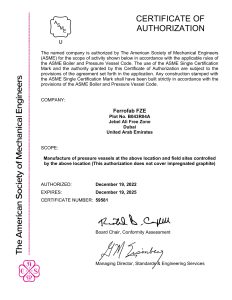

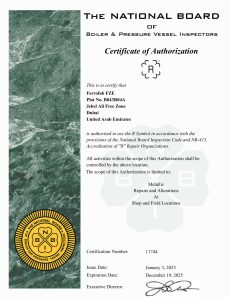

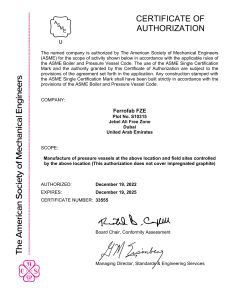

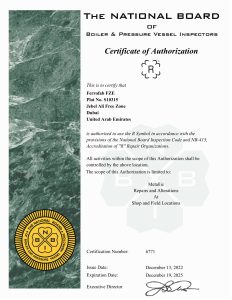

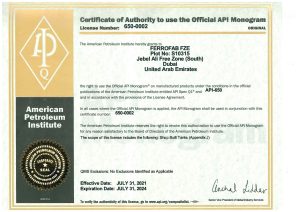

Certificates

Since 1998 we have a proven track record in audit and certification against a wide range of standards. With highly qualified engineers in place that build and deliver various practices that each project requires in the most efficient and finer way.